Engineering Services:

Area of Expertise:

Engineering: FEED, Design, Engineering, Project Execution, Construction & training for Oil & Gas, Petrochemical, Pharmaceutical, Power project, Water and Waster Water sector, Pulp & Paper Industry

Safety: Carrying out Process Hazard Analysis(PHA),Functional SafetyStudies (Safety Integrity Levels (SIL)/LOPA Studies, Management of Change(MOC),, Hazardous Area Classification,Environmental Safety and other safety related services

Training: Training on Instrumentation, DCS,PLC & ESDsystem,Functional Safety Training for Safety Instrumented system with respect to IEC 61508 & 61511

Engineering Services

- Design Engineering for Electrical and Instrumentation systems.

- Engineering from FEED, Design, Project Execution, Inspection, start up and commissioning

- Support services for Erection and Commissioning, Inspection and Training services

- Safety Integrity Level(SIL),Hazardous area Classification and Plant Safety Audit

- Training of Engineers for Electrical and Instrumentation

- Training on Functional Safety with respect to IEC 61508/61511 and Training of Field Engineers and Operators for Instrumentation

Process Engineering

- Preparation of PFD and P&ID based on project requirement in coordination with Process

- Process engineering support for Plant Modification/Retrofitting

- Process control narrative development

- Preparation of Process Documents (Equipment & Line List)

- Process Hazard Analysis (PHA) and Process Hazard Identification(HAZID)

- Hazard and Operability Study (HAZOP)

- Management of Change (MOC)

- Use of Various software based on Process

Piping Engineering

- Plot Plan, Equipment Layout and Skid Design

- Preparation of Piping Layout, Equipment list & Line list

- Equipment General Arrangement(GA) and Isometric Drawing

- Specifications based 2D/3D Piping Modelling, Design, Orthographic Plan, Section, and Detail Preparation

- Pipe Stress & Flexibility Analysis

- System Pipe Support Design and Piping System Walk downs

- GA Drawings & Isometrics, MTO for Piping, Valves and Insulation

- Preparation of final As built drawing based on field Mark up’s

- Piping System Revamp Engineering

Mechanical Engineering

- Mechanical Design & Analysis for Pressure Vessels

- Thermal and Mechanical design for Shell and Tube Heat Exchangers

- Design and detailing of Pumps, Blowers, Condenser’s, Heat Exechangers, Storage tanks and other mechanical equipment’s.

- Preparation of GA and fabrication drawings

- Use of Software packages based on the Project requirement

Electrical Engineering

- Design of Electrical System using ETAP

- Electrical Load list

- Single Line Diagram(SLD)

- Data sheet for Motors Local Control/Push button station and other Electrical devices

- Preparation of Electrical Schematics

- Design of Motor control Centre(MCC),Variable Frequency Drive(VFD)

- Electrical panel layout design,Lighting and Lightening System Design Earthing layout design

Instrumentation Engineering

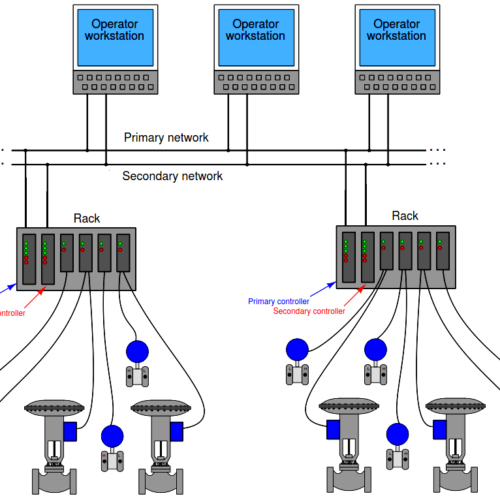

- Design of System Architecture for DCS, PLC,SIS F&G with SCADA System

- Instrument Specification & Instrument list based on P&ID

- Input/output List, Alarm & Trip schedule, C&E Matrix, BLD & Sequence flow Chart(SFC)

- Instrument & Control Narrative

- Review and support for FAT and SAT for control system.

- Review of Engineering documents for Electrical & Instrumentation

- Design of Control Panel with Internal Arrangement drawing

- Elect & Instrument Interface drawing

- Serial List for remote communication

- Instrument Location plan & layout Diagram,Instrument Hook Up drawing

- Cable sizing & Cable tray routing Diagram and Cable block Diagram.

- Preparation of specification and Sizing/Selection of Field Instrumentation and sizing of Flow elements,Control valves and Rupture Disc